Think testing roof heating cables is tricky?

It’s simpler than it sounds.

We’ll guide you through the process, step by step. From safety gear to troubleshooting tips, we’ve got you covered.

Key Takeaways

- Wear the necessary safety clothing and always follow manufacturer instructions.

- Have the right tools on hand, such as a multimeter, infrared thermometer, and ladder.

- Common issues to look out for include damaged wires, faulty connections, and incorrect installation.

- Test your cables annually before the cold season starts.

1. Preparation

First and foremost it’s vital to read the manufacturing instruction booklet to understand any instructions specific to your roof heating cable system. This is because different systems may have varying requirements and recommendations.

Gather your tools. You’ll need:

- Multimeter to check current, voltage, and resistance.

- Infrared thermometer to take surface temperature measurements.

- Megohmmeter to measure high electrical resistance.

- Ladder to reach your roof heating cables.

Always put safety first. You should:

- Wear rubber-soled shoes and non-conductive gloves to help protect you from electric shocks.

- Position your ladder on a stable surface to avoid any accidents. An assistant can be useful to help hold the ladder or pass your tools.

Here’s a quick checklist:

| Testing Instruments | Tools & Equipment |

|---|---|

|

|

2. Initial Visual Inspection

Once you’ve prepared with the necessary tools and safety gear, you should carry out a thorough visual inspection of the cables in your snow melt system.

- Examine the entire length of the cable for signs of wear, damage, or breaks.

- Check the connections to see if they are secure and intact and that the cable is securely connected to the power source with no exposed wires. Loose or exposed wires can lead to malfunction or even pose a safety hazard.

- Clear any debris, such as leaves, branches, or other obstructions, that might affect the cable’s performance.

3. Power Off and Disconnect

Before proceeding with any electrical tests, turn off the power to the heating cable system. This is a vital safety step as it removes the chance of electric shock or injury.

After powering down, safely disconnect the heating cables from their power source if needed for testing.

4. Test With Multimeter

You’re now ready to start your cable testing.

Begin with your multimeter to check the electrical integrity of your heating cables. This handy device tests voltage current and resistance so you can quickly tell if your electrical circuit is operating correctly.

Follow these steps:

- Set the multimeter to continuity mode. This setting will let you know if there is a continuous electrical path through the cable.

- Place the multimeter probes on the cable terminals. A beep or reading on the display indicates continuity. If there’s no continuity, it suggests a break in the cable, and you’ll need to replace or repair it.

- Finally, switch the multimeter to the resistance (ohms) setting. Measure the cable’s resistance and compare it to the manufacturer’s specifications. A reading significantly higher or lower than its specs means there’s probably a problem with the cable.

5. Power-On Testing

Power up your heating cables by plugging them into an electrical outlet or switching on the power via a dedicated switch.

If you want to check the performance of your roof heating cables in simulated colder conditions, now’s the time to adjust the thermostat setting.

Give your cables a few minutes to heat up and carefully touch them to feel if they are getting warm. If you get uniform heating along the entire length of your cable, you can rest assured it’s in proper working order.

6. Insulation Resistance Testing

Insulation resistance testing is essential to make sure your electrical insulation is in tip-top shape. It helps you to pick up on potential overheating, corrosion or moisture issues that could lead to electrical faults.

This is where your megohmmeter comes in. As it measures resistance, it also makes finding the location of faults easier for targeted maintenance and repairs.

Make sure your megohmmeter has a minimum testing voltage of 50V DC to measure the insulation resistance between your bus wires and your cable’s grounding braid.

How to carry out the test:

- Remove the outer jacket of the cable.

- Unwind the grounding braid.

- Remove the inner PTC core to access the bus wires.

- Connect each bus wire to the megohmmeter, ensuring they do not come into contact with the grounding braid.

Regardless of your cable’s length, you shouldn’t get a reading under 30 megohms. If you do, this indicates your cable or its insulation is probably damaged.

7. Infrared Thermometer Test

After doing a safety check, turn the power back on to your heating cable system. You are now going to use your infrared thermometer to measure the temperature of the cable along its entire length.

This test checks for uniform heat distribution through your roof deicing cables. If you notice significant temperature variations, it could indicate a fault in that section of the cable.

8. Final Inspection

Once you’ve finished your electrical and thermal tests, it’s important to recheck all connections.

- Make sure your connections are secure and there are no loose or exposed wires.

- Observe the system for a couple of minutes to check it heats evenly and operates without any unusual signs, such as inconsistent temperatures or visible sparks.

9. Document Results

Documenting your results and noting any issues makes it easy to keep track of the condition of your roof heating cables.

These records can also help a professional installer quickly pick up on past problems if complex repairs are needed.

10. Maintenance and Troubleshooting

You should regularly schedule maintenance checks if you want your roof heating cables to run optimally and efficiently.

- During maintenance, take new readings and compare them to the original values. If the readings fall below 30 megohms, inspect the cables and insulation for signs of damage.

- Remove sections that are physically damaged and replace them with new cables using an approved power kit.

- If you come across any “trip,” “low,” or “no current” problems during testing, it’s safest to replace these sections, even if there are no signs of physical damage.

For more complex issues or comprehensive inspections, consider hiring a professional. They have the expertise and tools to evaluate thoroughly and ensure your roof heating cables’ long-term efficiency and safety.

Additional Expert Tips for Testing Roof Heating Cables

The above steps will help you troubleshoot basic issues in your heating system. But there are other tests you can perform if you feel confident in your skills and level of electrical know-how.

1. Conduct a Cold Resistance Test

A cold resistance test is a great way to find out if your roof cable is performing optimally and reliably in low temperatures.

Take your multimeter and compare the measured resistance with the manufacturer’s specifications. If there are significant differences, it may indicate issues with the cable’s internal structure.

2. Check Your Current

If you have a cable that looks fine but is underperforming, a stabilized current test is a handy way for you to determine its power output accurately.

Use your multimeter to measure the current flowing through the cable after it reaches a stable operating temperature. You know there’s a fault if the current rating doesn’t meet its manufacturing specifications.

3. Use Thermal Imaging

For homes or buildings with large roofs, thermal imaging can identify cold spots.

Thermal imaging cameras are particularly useful for expansive areas where manual temperature checks are impractical, as they provide a detailed heat map of your roof heating cables.

This lets you visually confirm if your cables are heating uniformly and quickly pick up on the location of faults.

4. Monitor Voltage Supply

An unstable voltage supply could cause unreliable heating and reduced efficiency in your roof heating cables.

Use a voltmeter to check your voltage supply is consistent and within your heating cable’s range by testing multiple points along your cable.

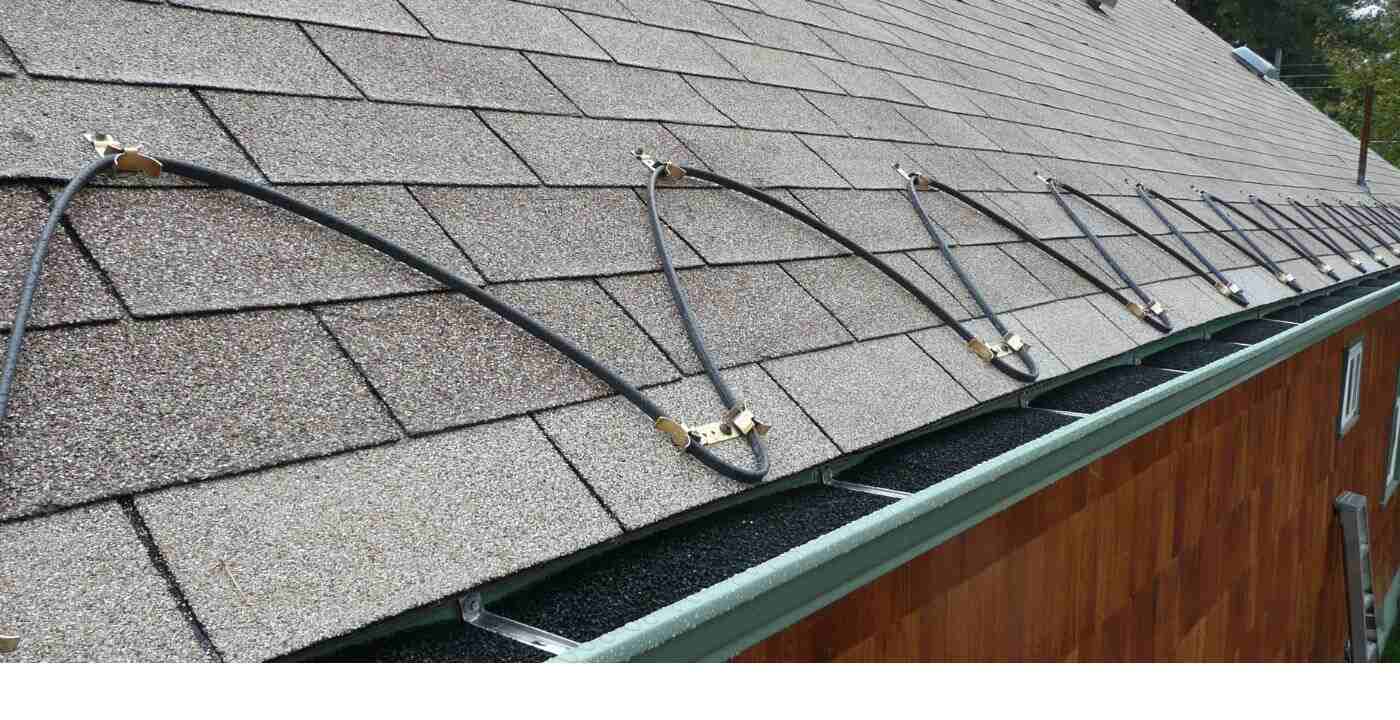

5. Installing and Testing with Gutter Guards

If you are installing roof heating cables together with gutter guards, make sure these don’t obstruct your cables.

Measure your roof and gutters accurately, and install the gutter guards first. Then, run the heating cables along the length of the roof and gutters.

Finally, test the system to ensure your heat cables warm up uniformly without interference from the gutter guards.

6. Consider Ground Fault Equipment Protection

Ground Fault Equipment Protection (GFEP) is needed in all commercial installations to meet NEC Code requirements.

Including this in residential installations adds an extra level of safety, as it detects ground faults and automatically cuts the power supply to prevent electrical hazards.

An easy way to include this in your roof heating system is to choose a control switch with GFEP protection. First, make sure it’s compatible with your selected cable voltage.

7. Advanced Troubleshooting

For advanced troubleshooting, start by comparing your new resistance and insulation readings against the original values taken at installation.

Inspect your cables for physical damage or insulation wear if these readings fall below the expected levels.

Consult a professional if you’re in doubt or dealing with a complex issue to ensure repairs are done correctly and safely.

Frequently Asked Questions

How long do roof heating cables last?

Roof heating cables typically have a lifespan ranging from 3 to 10 years, depending on the type and quality of cable you use.

How hot do roof heating cables get?

Roof heating cables usually have a maximum temperature of around 160°F (71°C). It’s important to remember though that their purpose is to melt ice and snow, rather than heating your roof.

Wired for Winter

Testing your roof heating cables is crucial in ensuring your home stays safe and warm during harsh winter months. By following these steps – from careful preparation to thorough inspections and electrical tests – you can maintain the efficiency and longevity of your heating system.

Remember, regular checks and proper maintenance are key to avoiding costly repairs and potential hazards down the line.

Ready to upgrade your roof’s winter defense? Our roof heating cables are designed for durability, efficiency, and easy installation. With our top-quality products, you can face the coldest months with confidence.